Material

One of the main aspects of the “Counter Entropy House” is the idea of saving energy accompanied by the issue of saving resources and thereby minimize solid waste. If possible materials are reused or at least can be recycled repeatedly.

Therefore the use of composite materials is tried to be avoided. This either is achieved by a construction that can be easily disassembled or by the material itself. For the “Counter Entropy House” for example old beams of the “Tivoli” stadium Aachen are used for the indoor and outdoor floor, as well as polished and melted CD‘s as facade panels.

The Tivoli Wood

As the city of Aachen recently got a new soccer stadium, the old one was torn down in Autumn 2011. The potential of old materials to be reused, was promising. The wood beams of the old roof were of particular interest for further usage in the Counter Entropy House. Of course it had to be tested, if those materials include pollutants that are not allowed to be used in private house building. Therefore wood samples were sawed out of the beams and brought to Aachen University Hospital. Although these beams were used in public area from 1980 on, Dr. Manfred Möller could certify that the material does not include harmful substances. Under this prerequisite and with permission of the city of Aachen, the huge wooden beams were sawn to manageable blocks and trucked to the University. Afterwards the former „Tivoli-beams“ got sawn to panels that will be used for the floor inside and outside. As after treatment and to get the new panels weather resistant, they got oiled. This way polluting paints are avoided.

Facade

After several studies regarding recyclable materials that could be used for our façade, the Counter Entropy team opted for CDs as the best solution. CDs are made from polycarbonate, which is aluminized and coated with protective paint and print ink. Since they are more and more replaced by other data storage solutions, there is a fair amount of them available. Lots of collecting events led to thousands of CDs, which can be used for our house. In addition we are in close contact to waste disposal stations in Aachen and its surroundings, where old CDs are provided for the Counter Entropy Team.

From the original idea of a CD façade to its final production there is a long way of research and development. Gentle shingling and optimal protection from driving rain, low energy consumption during production, but also aesthetics and stability are points the material group had to consider during development.

Our final solution – fusing the CDs to panels – was agreed on after lots of studies regarding the shingling, the composite technology and the substructure. Using fuse technology we don’t have to work with toxic compounds and ensure sufficient stability at the same time.

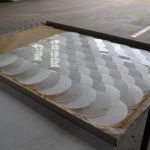

The CDs are shingled on metal sheets from old metal racks and melted in an oven to form the panels.

The ideal baking temperature, -duration and cooling rate resulted from several studies conducted by the Façade Team in close collaboration with the AVT (Aachen Institute for Process Engineering). To create a uniform white surface under the translucent layer of CD panels and improve the weatherproofing at the same time, the frames of the substructure are covered with recycled truck canvas before the panels are attached.

Contact Person

Pascal Martis